Our Capabilities

Our vertically integrated facility enables us to provide extraordinary quality and product possibilities with speed-to-market solutions. We offer ingenious and premium knitted products with functional finishes and a wide range of prints.

HP Cotton

HP CottonSophisticated facilities and superior-quality yarn for best outcomes

HP Cotton is a vertically integrated facility from knitting to garmenting, sourcing superior-quality yarns to produce the finest knitted fabrics and garments to meet the distinct needs of our clients worldwide. Our production facility in eastern India houses hi-tech machinery and equipment spread over a 7 lakh sq. ft. operating area with a production capacity of 18 million pieces per annum.

We manufacture garments with knitted fabrics produced in our mills and deliver them to several high-end retailers and brands worldwide. We are meticulous about the products we manufacture and ensure high-quality standards and safe working conditions, adhering to ethical practices. We ensure, the well-being of our people and environment with eco-friendly and sustainable practices.

Capabilities

| Make | Model | DIA | Gauge | Type | Nos of Needles | Feeders | Year | Nos Of M/C’s |

| KAUO HENG | – | 80″ | 16 | Flat Knit | 4020 | NA | 2023 | 4 |

| Mayer&Cie | D4-3.2 II | 34″ | 24 | Interlock | 2544 | 108 | 2023 | 2 |

| Mayer&Cie | D4-3.2 II | 34″ | 28 | Interlock | 2976 | 108 | 2023 | 2 |

| Mayer&Cie | D4-3.2 II | 34″ | 32 | Interlock | 3408 | 108 | 2023 | 2 |

| Mayer&Cie | D4-3.2 II | 34″ | 36 | Interlock | 3844 | 108 | 2023 | 2 |

| Mayer&Cie | S4-3.2 II | 34″ | 24 | Openwidth Single Jersey | 2544 | 108 | 2023 | 1 |

| Mayer&Cie | S4-3.2 II | 34″ | 28 | Openwidth Single Jersey | 2988 | 108 | 2023 | 4 |

| Mayer&Cie | S4-3.2 II | 34″ | 32 | Openwidth Single Jersey | 3408 | 108 | 2023 | 4 |

| Mayer&Cie | D4-2.2 II | 34″ | 18 | RIB | 1920 | 72 | 2023 | 2 |

| Mayer&Cie | D4-2.2 II | 36″ | 18 | RIB | 2016 | 76 | 2023 | 4 |

| Unitex | UBX 1.5TR | 30″ | 20 | Terry | 1884 | 45 | 2023 | 1 |

| Mayer&Cie | S4-3.2 II | 34″ | 24 | Tubular Single Jersey | 2544 | 108 | 2023 | 8 |

| Mayer&Cie | S4-3.2 II | 30″ | 28 | Tubular Single Jersey | 2640 | 96 | 2023 | 3 |

| Mayer&Cie | S4-3.2 II | 34″ | 28 | Tubular Single Jersey | 2988 | 108 | 2023 | 8 |

| Mayer&Cie | S4-3.2 II | 34″ | 32 | Tubular Single Jersey | 3408 | 108 | 2023 | 3 |

| 50 |

HP Cotton’s apparel manufacturing process comprises knitting, dyeing and finishing. Our dyeing requirements are handled at the Hunaram Processing facility, which houses computer-aided and latest machinery and has the capacity to produce 30 tonnes per day. Each step of the production process is subject to stringent quality checks by our quality control team. We optimise efficiency and ensure product quality by enhancing systems and processes.

Before proceeding with the dyeing process, the quality control team performs various tests on the dyed fabric samples and compares them with the customer-approved samples to ensure the accuracy of the dyed colour.

In adherence to our commitment to environmental safety, Hunaram’s production unit is equipped with a fully functional Effluent Treatment Plant (ETP) to ensure zero liquid discharge. Water is a crucial resource in the textile manufacturing process and a huge volume of wastewater with harmful chemicals/contaminants is released into the environment, polluting water quality. Hunaram limits the release of hazardous waste with fully functional Effluent Treatment Plants ensuring environmental safety.

Wastewater from the textile manufacturing process contains high levels of TSS, dyes, chemicals & auxiliaries, metal toxicants and BOD. Our ETPs efficiently remove these toxic pollutants in compliance with environmental regulations, improving the quality of water as per accepted norms before being discharged into the environment, minimising environmental threats.

| Tubular | ||||

| Machine Details | No of Machines | Make | country | Production |

| wet Stretch & Balloon Padding | 2 | Ferraro | Italy | 16000 kgs/Day |

| Tubular compact – Single pass | 2 | Ferraro | Italy | 8000 Kgs/Day |

| Tubular compact – Double pass | 2 | Ferraro | Italy | 9000 Kgs/Day |

| Relax dryer 4 pass – 2 chamber | 1 | Entema | Turkey | 12000 Kgs/Day |

| Open Width | ||||

| Machine Details | No of Machines | Make | country | Production |

| Slit Opener Cum open width padder with Bio – wash Cleaner | 2 | Ferraro | Italy | 12000 Kgs/Day |

| Stenter – Heat setting cum open with dryer, Mahlo weft straightner with EdgeCutter (8 Chambers) | 1 | Monforts | China | 12000 Kgs/Day |

| Stenter – Heat setting cum open with dryer, Mahlo weft straightner with EdgeCutter (10 Chambers) | 1 | Monforts | China | 15000 Kgs/Day |

| Open Width felt Compaction | 2 | Ferraro | Italy | 8000 Kgs/Day |

| Make | Vessel Size – Capacity – 20 Tons/ Day | |||

| Fongs – China | 300, 600, 900, 1200 | |||

| Pranav – India | 25, 50, 200 | |||

Rotary Printing:

Our production facility houses sophisticated Zimmer machinery for rotary printing, with the capability to produce 6 tons of rotary printing per day. It’s a continuous printing process where colour pigments are applied onto the fabric through a perforated cylindrical screen, and multiple screens are used for different colours.

Rotary printing offers enhanced production efficiency and is an apt choice for long production cycles and superior surface applications.

Research and Development:

HP Cotton’s in-house design and R&D team seamlessly integrate customer requirements to offer compelling,

appealing and stylish lifestyle fabric and garment solutions leveraging our core specialities in blended

knits, dyeing and printing. We produce fabrics and garments of superior-quality with quick quality approvals

and turnaround time.

Fabric:

HP Cotton’s Fabric R&D is at the cutting edge of fabric innovation with a vision to offer our customers a

wide range of original fabrics with custom aesthetics and functions. Our team comprises a dedicated bunch of

textile engineers with experience and smart working skills in advanced technology to create new knit

structures and finishes inspired by trend analysis, international trade shows and client needs.

- Our ultimate goal is to focus on fibre to fashion in the garment industry.

- Extensive research to gain insights into innovation in fibre, yarn, materials, and finishes.

- We work with textile mills to anticipate and co-create fibre/fabric or finish technologies.

- We strive to fill the gap and improve fabric development and technology.

- Analyze and review fabric tests to evaluate the type of risks and recommend improvement opportunities.

- Provide insights on creating profitable and environmentally sustainable garments.

- Utilize our R&D team to create custom fabrics that inspire your garment designs, minimizing fabric constraints to weave innovation into your clothing brand.

Designing:

Design development and sampling form the core aspect of our operations and help distinguish our business

from our competitors. Our design team consists of qualified designers and an active library of over 50000

designs for knits, with an average of at least fifty new designs being added to our portfolio each day.

HP Cotton’s design development and extensive design database enable us to make a style statement in the fashion industry. We offer exclusive component innovation with excellent service delivery from concept development to production.

Product development:

HP Cotton’s in-house product development team utilize CAD (Computer Aided Design) tools to deliver creative

textile and apparel designs with dedicated teams to service our key clients. We conduct extensive research

to gain insights into the latest trends in the apparel industry which helps us produce myriad garment

collections for potential and existing clients consistently throughout the year.

Our design team has comprehensive knowledge of various fabrics and finishing technologies and works directly with customers offering innovative and cost-efficient solutions to various design challenges. Our design team works in partnership with customers to experiment and develop samples to minimize the resources needed for product development.

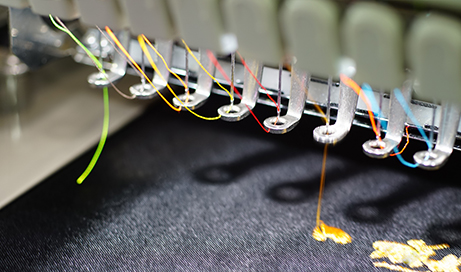

Embroidery and Printing:

Our production unit houses hi-tech machines for sampling in embroidery (Tajima make) and printing and an

exclusive design team for executing R&D in embroidery.